I. The layout way of the charging car and induction furnace

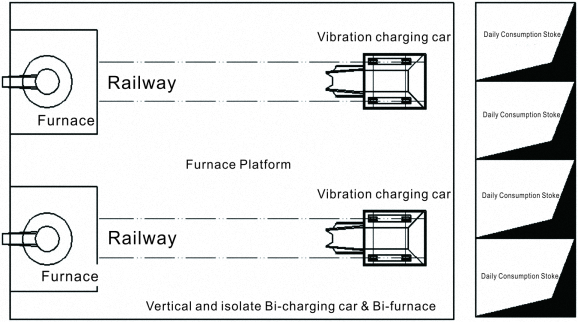

Design proposal 1: charging in vertical shift

Each furnace equips one charging car, vertical shift charging, with isolated charging. The advantages are isolate, reliable, high charging efficiency, multi furnace working meanwhile and don’t affect each other, and also each other for standby, but the disadvantage is the investment of charging cars once set up is huge.

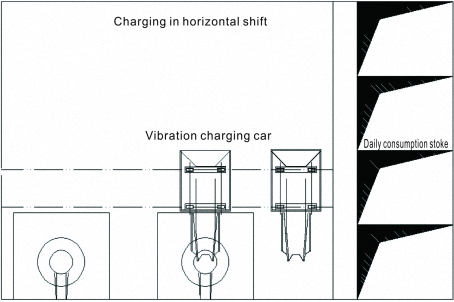

Design proposal 2: charging in horizontal shift

Charging car moves in horizontal that can charge for two or more furnaces. The cost of one charging car for two furnaces is only the half of the longitudinal charging way, but the disadvantages is that if the charging car gets malfunction which will cause the furnace can’t be charged, and also consider the car discharge entrance not match with the furnace cover position.

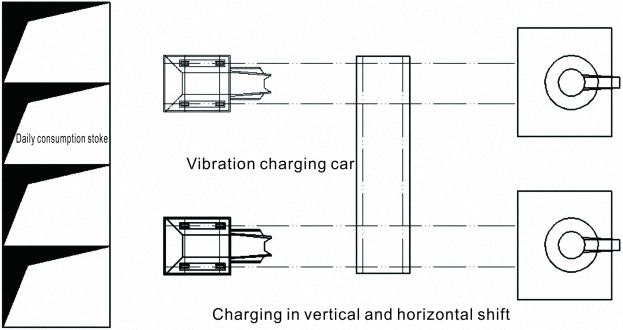

Design proposal 3: charging in vertical and horizontal shift

There are vertical rail and the horizontal rail, the charging car can charge two paratactic furnaces in vertical and horizontal, more than two furnaces can share one charging car, one car for two furnaces (more furnaces), less investment, the disadvantage is that bi-direction moveable mechanism and the car structure is complicated, the fabricating cost higher, the rail is higher than the platform, it is inconvenient, and the maintenance is not easy. This charging way isn’t adopted always unless the obstacle is adopted (such as column).